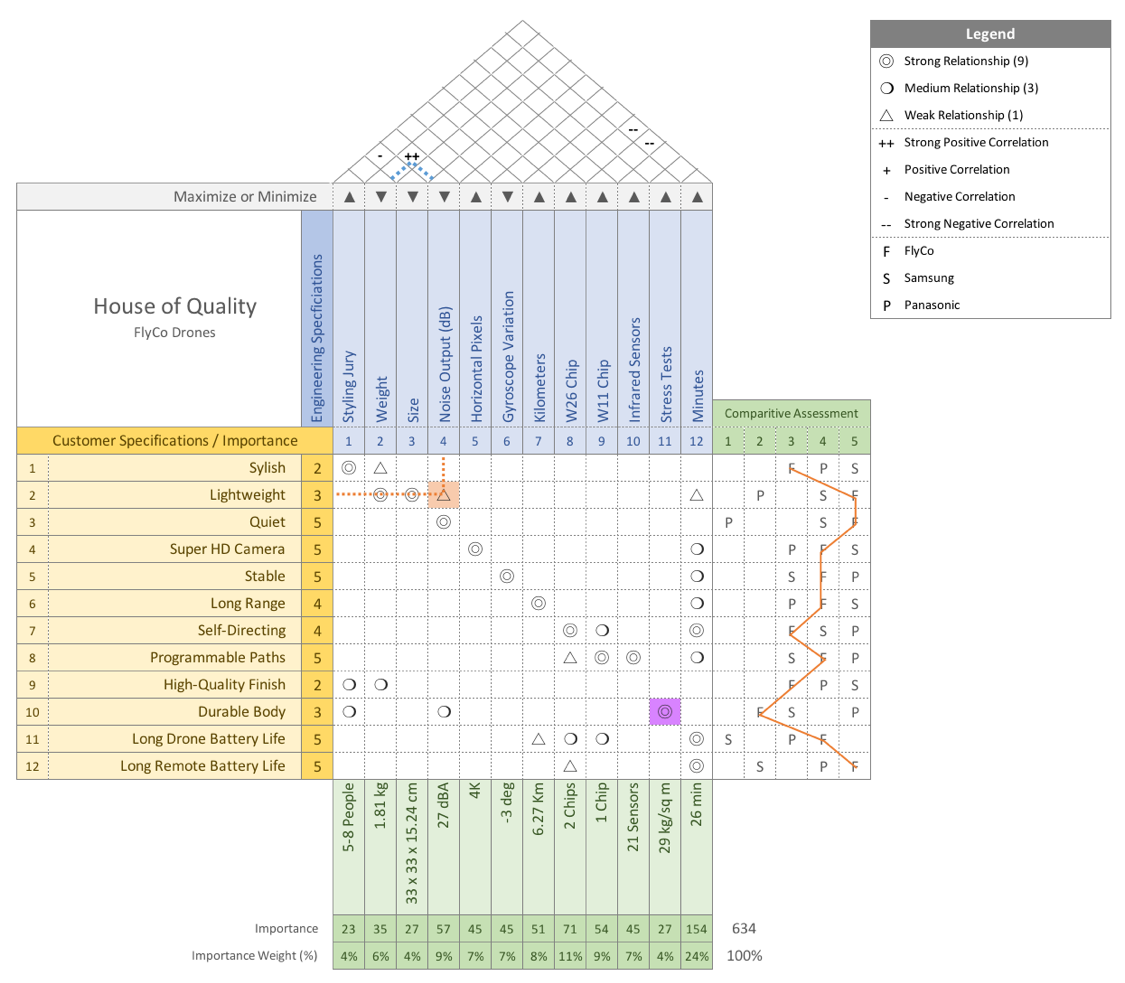

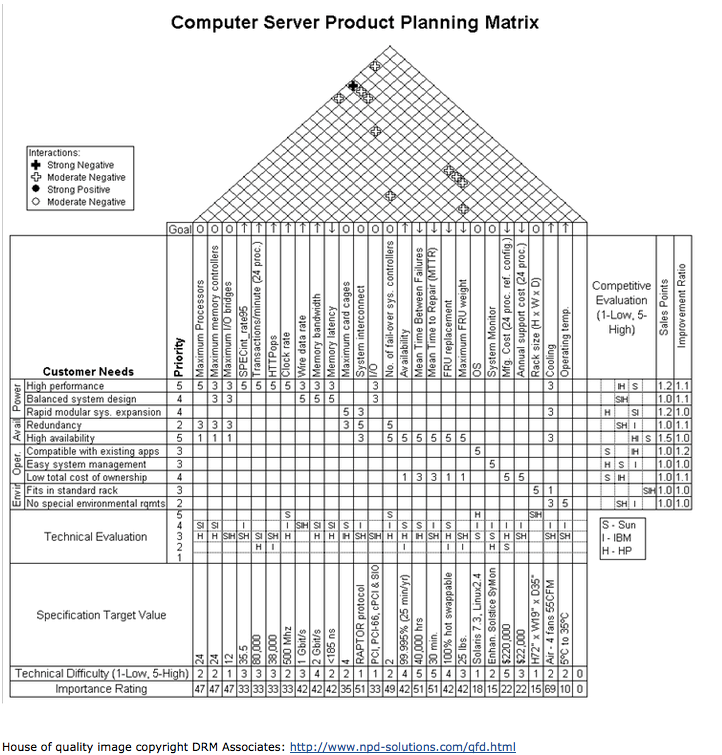

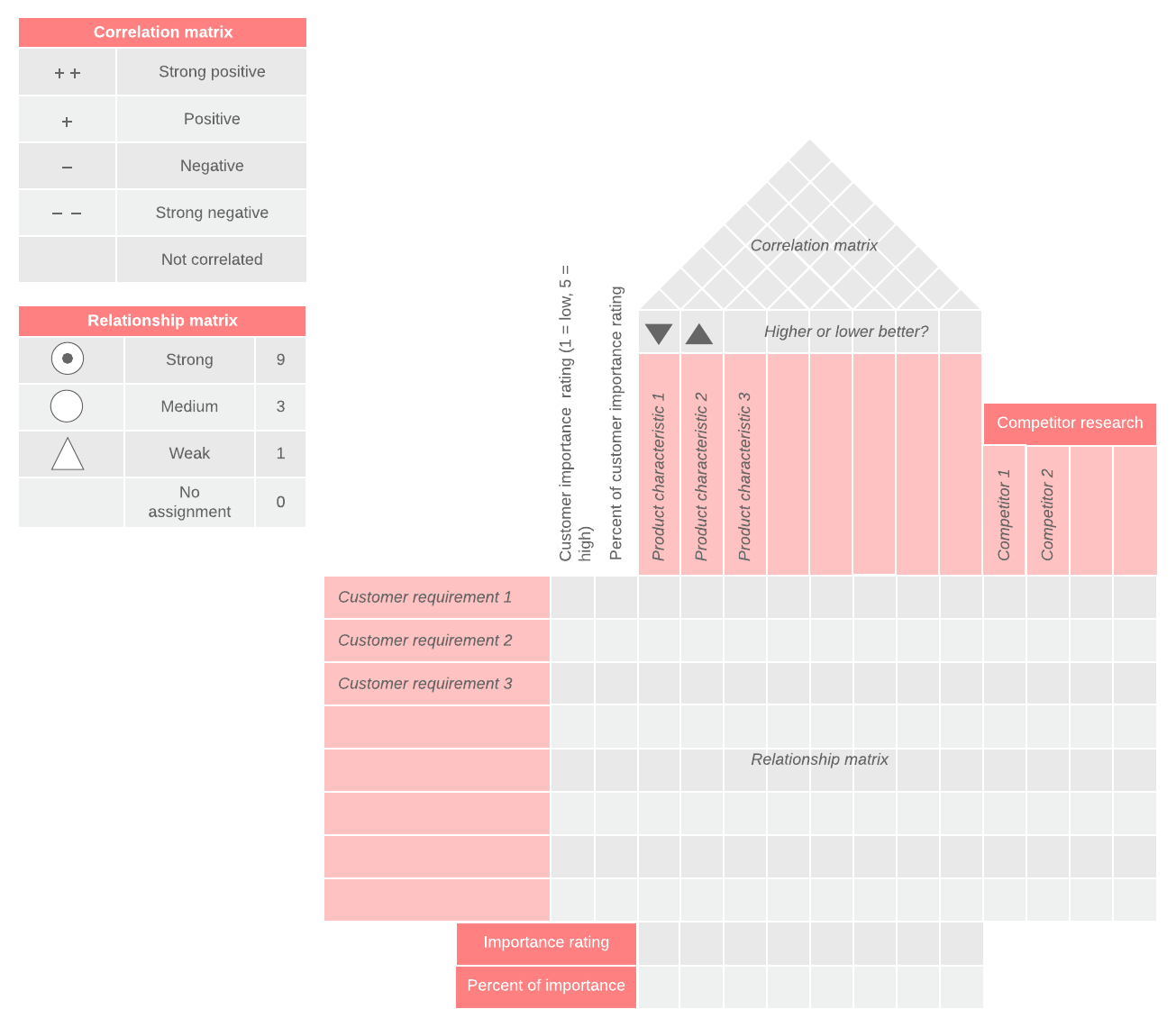

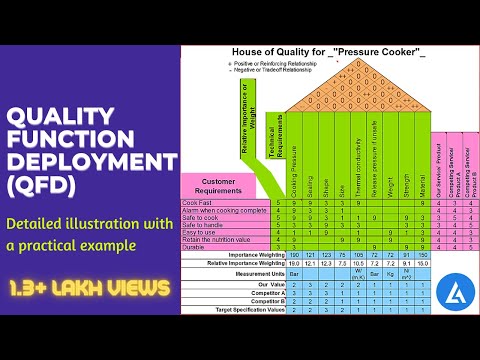

House of quality diagrams use a design that resembles the outline of a house and can be created using technical and competitive benchmarking data.

House of quality roof explained.

It is a process of listening to customers translating their desires into a written plan prioritizing steps of execution based on what is most important.

Yoji akao the original developer described qfd as a method to transform qualitative user demands into quantitative parameters to deploy the functions forming quality and to deploy methods for achieving the design.

Definition of house of quality.

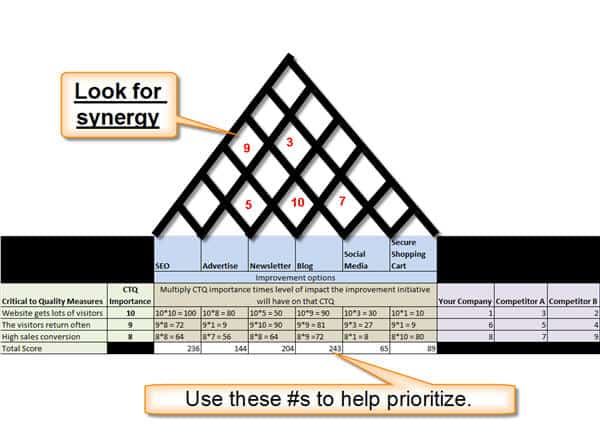

The house of quality s distinctive roof matrix helps engineers specify the various engineering features that have to be improved collaterally see exhibit ix.

The house of quality is a voice of customer analysis tool and a key component of the quality functional deployment technique.

The house of quality or quality function deployment is a useful tool that six sigma black belt practitioners use during the define phase of the dmaic cycle of six sigma projects the topic can be briefly discussed in green belt training or sometimes on online free six sigma courses however the house of quality is one of the more advanced lean techniques.

How to build a house of quality.

House of quality refers to a well known process for product development that is inspired by customer desires for product or process development and anchored by the capabilities and resources of the organization seeking to meet those desires.

The matrix gives us details such as customer requirements technical descriptors priority levels of the various descriptors the relationship between the.

It starts with the voice of the customer.

It is a tool to translate what the customer wants into products or services that meet the customer wants in terms of engineering design values by way of creating a relationship.

The house of quality is the first matrix in a four phase qfd quality function deployment process.

House of quality is actually a matrix and is also termed as quality matrix.

Quality function deployment qfd is a method developed in japan beginning in 1966 to help transform the voice of the customer into engineering characteristics for a product.

To improve the window motor you.