Glass fiber reinforced concrete gfrc panels are comprised of a 1 thick composite glass fiber concrete skin that is mechanically attached by flexible steel pins to a sturdy steel frame.

Ingredients for gfrc wall panel.

What are gfrc flex anchors for.

Precast gfrc precast gfrc and cast stone both have their benefits and drawbacks.

Portland cement lime and sand.

Sandwich panels may be used where a gfrc outer wall and gfrc inner wall are desired.

Apart from fiberglass the mix for gfrc also includes cement acrylic polymer fine sand aggregate and other performance admixtures.

Gfrc glass fiber reinforced concrete is lighter stronger faster than normal concrete.

This expressions ltd basic gfrc mix recipe works great for gfrc countertops sinks and furniture pieces.

Flex anchors are rods usually bent stainless steel that act as attachments to hold the gfrc skin to the metal stud frame and allow some minor movement between the gfrc face of the cladding and the steel frame.

Our gfrc wall panels are typically made at 3 4 1 thick.

Cladding concepts is the proud united states partner for polycon brand glass fiber reinforced concrete.

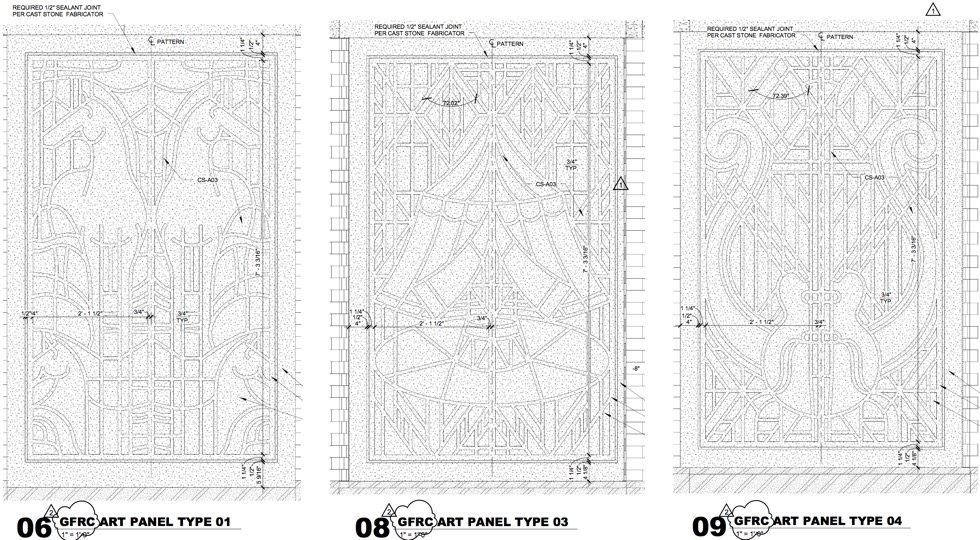

28 story hotel with gfrc cornice bands vertical columns and art features.

Formglas gfrc l is similar to traditional gfrc in appearance except for the absence of a steel frame backing.

Gfrc panels are an excellent choice for high rise buildings in areas of high seismic activity and for very decorative and intricate shapes and applications.

Beginning from the first to the last the coats are generally called.

Gfrc l is commonly used in low rise exterior facades for applications such as panels which are generally cast to an installation friendly maximum size of 3 x 4 decorative elements such as cornices window and door frames and friezes and in certain high traffic interiors where.

Gfrc pieces can be de molded as early as 24 hours.

With a custom concrete wall panel designers do.

While using gfrc for a project can be slightly complicated the benefits often greatly outweigh the added complexity.

Polycon products made in czech republic and trusted as the worlds highest quality gfrc glass fiber reinforced concrete panel.

On wood stud and cold formed steel stud wall assemblies stucco is typically applied in three coats.

Since there are no stone aggregates or metal reinforcing within a standard wall panel gfrc can be cut as easily as natural stone tile allowing you to order one generic size for efficiency or still design each wall panel to a custom size.

It s made by combining a mixture of fine sand cement polymer usually an acrylic polymer water other admixtures and alkali resistant ar glass fibers.

Gfrc panels wall cladding systems.

Harrah s poydras street hotel view project.

Gfrc cornice arch and ceiling panels.

Scratch coat brown coat and finish coat.

Many mix designs are available online but you ll find that all share similarities in the ingredients and proportions used.

This hospital had originally been clad using eifs wall panels designed to simulate stucco but gfrc was chosen for its strength.